English

English

English

English

1. What is a submersible pump?

First question to all non-engineers. You can find the answer very easily, you can go to google type the question, there will be a bunch of answers from the same websites both in terms of content and images. But these answers are very general in nature, if you really want to understand more deeply I would like to share some of my knowledge about this pump.

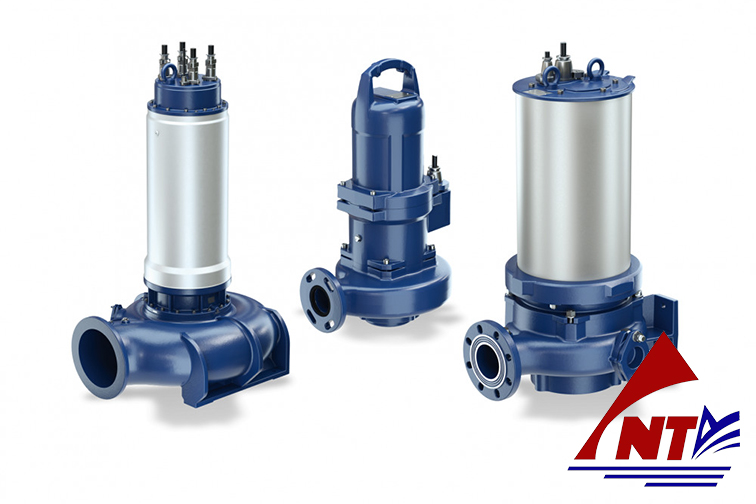

Some pictures of popular submersible pumps

Submersible pumps, of course: this is a pump that uses an electric motor, the pump is completely submerged in water with the motor sealed and fastened to the pump.

Is this answer completely correct now? please share with you that it is not completely accurate. Go back in time to the day the submersible pump was born. First of all, in 1928, Armenian engineer Armais Arutunoff invented the first submersible oil pump in an oil well in the El Dorado oil field near Burns, Kansas. But in 1929, Pleuger Pumps (today Pleuger Industries) pioneered the design of the submersible turbine pump, the forerunner of the modern multistage submersible pump. Its first product was a submersible motor pump for dewatering in underground railway and subway construction. Pleuger pioneered the first successful application of a submersible motor pump in offshore service.

What about today? Do submersible pumps have to be completely submerged in water? The correct answer is no. Thanks to modern technology, today's submersible pumps have been developed with an enclosed electric motor cooling solution, so the current submersible pump can both function as a conventional submersible pump and can also operate at the same time. partially operate the pump submersible in water and operate normally as a dry-running installation pump.

Submersible pump with cooling jacket

Here we are considering the operation of the submersible pump fully or partially in water, while the submersible pump can run dry which I will introduce in a next post.

The operation of a submersible pump is a little different from that of a Jet pump. Because the Tia pump transfers the liquid by pulling it while the submersible pump transfers the liquid by pushing it. Submersible pump is a kind of centrifugal pump. Therefore, its working way is very similar to other types of centrifugal pumps.

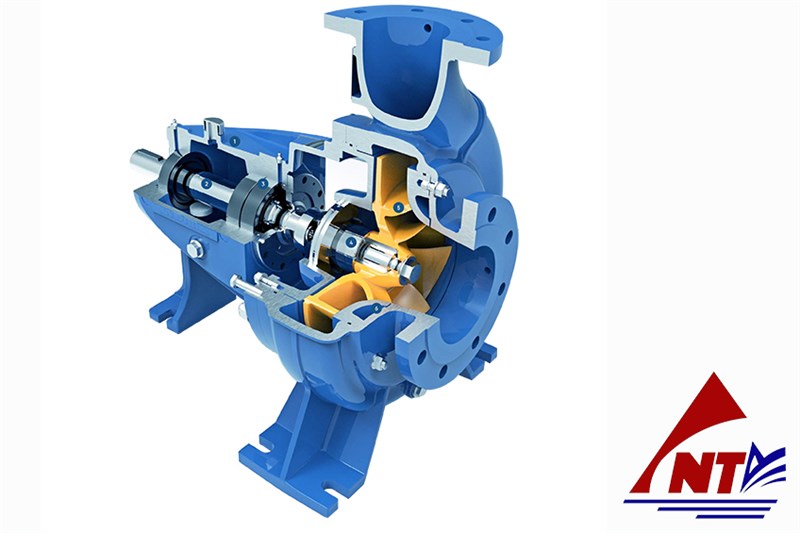

During the working of the submersible pump, it will push the water towards the surface. When well water or storage tank enters the pump by foot valve, it will hit the impeller. The impeller is a rotating part with many fixed blades. This impeller is connected to the electric motor through a shaft. The impeller rotates with the rotation of the shaft.

When the water hits the blades of the impeller, the blades convert the kinetic energy of the water into speed and increase the speed of the water. After passing through the impeller, the water enters the diffuser, further converting the speed of the water into pressure energy. In this way, the diffuser increases the desired pressure of the water; then, pressurized water discharges through the pump outlet valve.

In this way, the submersible pump pushes water to the surface

.png)

working principle of submersible pump

There are many types of submersible pumps, so to distinguish them, we can rely on submersible pump construction, classification by impeller type, application, etc. they are installed in wells, tanks, substations, etc.

We will talk first to the most common type of submersible pump, which is a submersible well pump, also known as a deep well submersible pump, well pump, rocket pump.

Well submersible pump

If you live in a town or city, you may not think much about how the water you use every day reaches your home. Even small villages often provide a network of water pipes that transport water to every house in the neighborhood. All you need to know is how to turn on the faucet at the sink.

Move a few dozen kilometers out of the town center and the picture is subject to change. While the inner workings are still functioning normally, your water supply is independent and separate from your neighbours. Each house has its own well to draw water. Moreover, each house has its own electromechanical system to get water from the well. At the heart of each system is a pump, and the most common types are submersible well pumps.

In many parts of the country, finding drinking water is as easy as grabbing a shovel and digging a hole in the ground. Maybe "easily" isn't the right word, but wherever the water table is just a few meters above the ground, the draw is over. In such a shallow well situation, it's a little easier to get water up, if only because the distance you have to travel is really short, we can think of communal yard wells.

Well water

If your area doesn't have a high water table, or if it lacks a steady supply of drinking water near the surface, you'll have to dig deeper to achieve the same results. And because a deep well means water has to be fetched farther up, the strategies for moving it will change.

Today, the most common pump for shallow wells is the high thrust pump. The high-pressure pump is installed above the well, indoors or right above the well mouth, and draws water up from the well through suction. Because suction is involved, barometric pressure is what's really working. Think of the system as a long straw. When you suck on a straw, you create a vacuum in the straw above the water. When the vacuum is there, the weight of the air, or atmospheric pressure, pushes the water up the straw. Therefore, the height to which you can lift water with a shallow well pump is related to the weight of the air. Although the air pressure varies with altitude, it is common to limit the depth of a shallow well operated by a high-pressure pump to between 7-8 m.

Dry well water

High thrust pumps create suction in a rather novel way. The pump is powered by an electric motor driving an impeller, or a centrifugal pump. the impeller moves water, called drive water, from the well through a collection hole, which is mounted in the housing in front of the impeller. This narrowing at the nozzle causes the speed of the water to move up, like the nozzle on a garden hose. As the water leaves the jet, a partial vacuum is created to draw more water from the well. Directly behind is a Venturi tube increasing in diameter. Its function is to slow down the water and increase the pressure. The pumped water - fresh water drawn from the well by suction at the hose - then combines with the drive water to discharge into the plumbing system at high pressure.

Because shallow well injection pumps use water to draw water, they often need to be primed – filled with water – before operating. To keep the water in the pump and plumbing from flowing back into the well, a one-way check valve is installed in the pump inlet line. here is usually the bottom valve.

Unfortunately, you may have to go a little deeper than 8 meters. Surprisingly you can still do that with the Jet pump. It simply consists of separating the nozzle from the engine housing and impeller and placing the nozzle assembly in the water. In a typical deep well Tia pump configuration, a pipe fitted with an impeller housing carries water down to the nozzle body which is located at least 3 to 6 m below the well water level. A second pipe connects the outlet side of the nozzle body back to the pump

Jet pump

At the injector, an increase in water velocity creates a partial vacuum that draws well water from the well to the second pipe and back to the pump and plumbing system. The Deep Well Beam pump uses both suction at the nozzle to bring water into the system and the pressure created by the impeller to lift the water.

To avoid overfilling of the well, the installation of the Jet pump for a deep well may include a discharge pipe longer than 10m. It is connected to the nozzle inlet and extends down the well. If the water level drops below the level of the nozzle, the pump operates in the same way as a shallow well pump. While the flow rate decreases, water will be available until the water level drops below about 8 m from the nozzle - the limit for a shallow pump. The 10 m long drain hose effectively ensures that the well will never be pumped out. Of course, the aircraft's altitude above the waterline affects performance. The further away it is, the less efficient the pumping becomes.

While a Jet pump can reliably handle wells several tens of meters deep, a more efficient solution is to move the pump down the well so that instead of lifting the water, it pushes it up. A typical well submersible pump is characterized by a long cylinder that fits inside the well casing. The lower half is made up of a sealed pump motor that is connected to the upper power supply and is driven by wires. The actual pump half consists of a series of stacked impellers - each separated by a diffuser - that help direct water up the pipe to the plumbing.

Pumping system for shallow wells and deep wells

In modern installations, the well casing outside the house is connected to the plumbing system by a pipe that runs underground to the basement. This horizontal pipe joins the well pipe at a connector called a holeless adapter. The function of the adapter is to allow access to the pump and well piping through the top of the well casing, and to route water from the pump into the plumbing.

While a submersible well pump is more efficient than a Tia pump at delivering more water to a motor of the same size, pump or motor problems will require pulling the unit out of the well casing - work The best job should be left to a professional. However, submersible pumps are renowned for their reliability and typically perform their role for 20 to 25 years without maintenance. Submersible pumps can also be used in shallow wells. However, silt, sand, algae and other contaminants can shorten the life of the pump.

Regardless of the type of system you have, the components on the outlet side of all pumps are similar.

Pumps are not intended to run continuously, and they do not start every time you open the faucet or flush the toilet. To provide consistent water pressure at the units, the pump first transfers the water to the storage tank. Inside a modern sump is a tank of gas that will be compressed when water is pumped in. The pressure in the tank is the factor that moves water through the plumbing system in the home.

When the pressure reaches a preset level, which can be between 2.5 and 4 bar, a switch stops the pump. When water is used in the home, the pressure begins to decrease until, after a drop of about 1.5 bar, the switch turns on the pump and the cycle is repeated. You will find the pressure gauge mounted on the tank with the wires leading to the switch that controls the pump.

Articles about submersible pumps continue to be updated....

Hanoi August 28, 2021- Posted by Mr. Water

0964633986

Từ khóa tìm kiếm:

|

NTA PUMP ENGINEERING COMPANY LIMITED C4 Vu Ngoc Phan str, Lang Ha ward, Dong Da Dist, Hanoi city. |